Exploring the Trick Benefits of Membrane Switch Over in Innovative Styles

In the world of item layout, the assimilation of membrane layer switches over deals remarkable advantages, particularly in terms of resilience and reliability. These switches, constructed with layered, versatile materials, endure rigorous conditions and repeated usage, an important advantage for devices exposed to severe atmospheres. Their inherent resistance to dirt, chemical, and water invasion additionally highlights their suitability for numerous commercial applications. This toughness, incorporated with their visual and practical versatility, placements membrane layer switches over as a compelling choice for developers intending to merge longevity with innovation.

Enhanced Toughness and Reliability

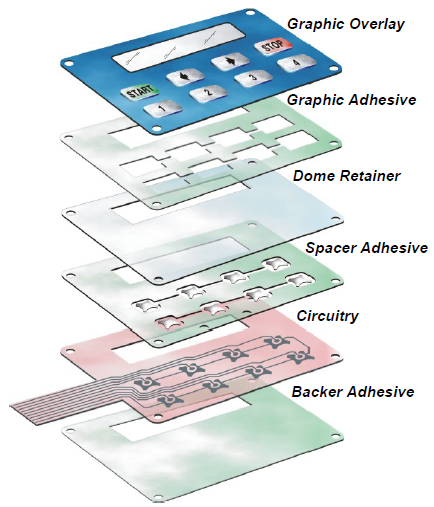

Membrane layer buttons are renowned for their boosted durability and dependability, connects that stem from their distinct building and construction. These switches are composed of layers including a graphic user interface layer, a conductive ink circuit, and a dielectric layer, all sealed against environmental elements such as wetness and dust. Membrane Switch. This layering not only shields the inner parts but also makes sure that the button features under a series of adverse problems

Membrane layer buttons additionally run properly in a wide variety of temperatures and are resistant to vibrations, making them optimal for use in both industrial and customer applications where reliability is essential. Membrane Switch. Their robust building causes fewer failures and maintenance requirements

Customization and Visual Adaptability

Past their architectural benefits, membrane layer changes deal considerable personalization and visual adaptability to satisfy varied design needs. The graphic overlay, which is the hop over to here leading layer of a membrane button, can be printed with personalized graphics, logos, and message, making each application unique while sticking to brand guidelines.

Additionally, the capacity to integrate transparent home windows for LCDs or LEDs and tactile features such as embossing improves the user experience. These choices permit for the creation of a multi-dimensional user interface that is not just practical but likewise adds to the overall product visual appeals. By leveraging these customization abilities, manufacturers can create distinct items that stand out in open markets.

Cost-Effectiveness and Relieve of Combination

Additionally, the flexible and thin nature of membrane switches allows for uncomplicated assimilation right into different applications, from advanced clinical devices to consumer electronic devices - Membrane Switch. In addition, membrane switches are suitable with countless substratums and adhesives, improving their adaptability throughout different industries.

Verdict

Finally, Click This Link membrane layer changes stick out as a robust alternative in ingenious designs, supplying boosted longevity and dependability essential for sustaining extreme conditions. Their ability for personalization supports a variety of visual preferences, making them functional for different branding demands. Additionally, their cost-effectiveness and ease of combination assist in swift and reliable product advancement, positioning membrane layer changes as a very beneficial selection for designers intending to balance capability, style, and marketability in affordable industries.

In the world of product style, the assimilation of membrane switches deals notable benefits, especially in terms of sturdiness and integrity.Past their architectural advantages, membrane switches offer considerable customization and aesthetic flexibility to satisfy diverse design demands.While personalization boosts visual allure and use, membrane layer buttons additionally give significant cost advantages and ease of combination that benefit suppliers and end-users alike. The production process for membrane layer switches over entails less products and much less labor contrasted to standard mechanical switches, which directly see here now translates into reduced manufacturing expenses.In final thought, membrane changes stand out as a robust option in innovative designs, offering boosted toughness and integrity critical for sustaining harsh conditions.